Cementing our future: QUT discovers process to capture CO2 emissions

Queensland scientists had made a major breakthrough that could help reduce carbon dioxide production from one of the major industrial contributors to climate change gases.

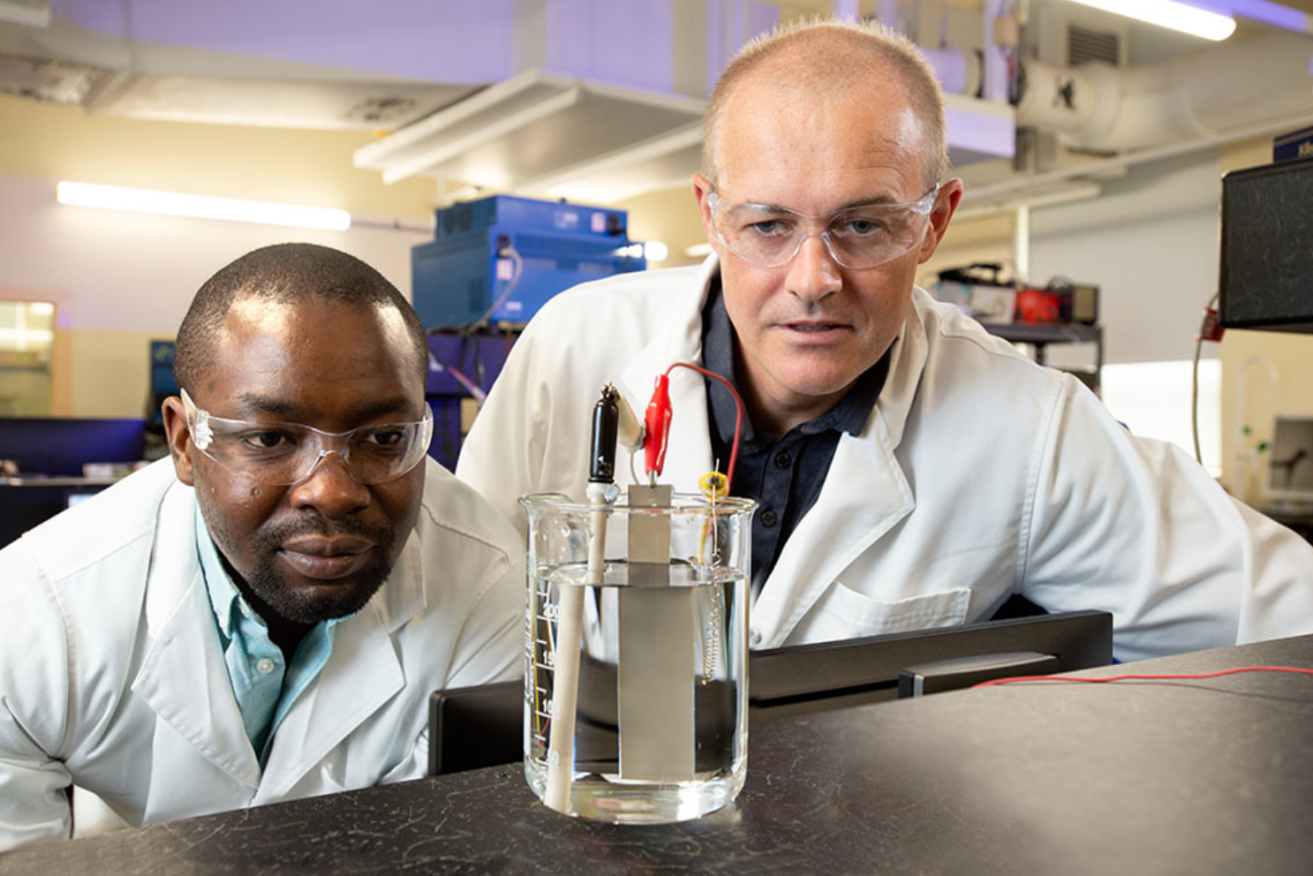

PhD researcher Olawale Oloye and Professor Anthony O'Mullane

The QUT Centre for Clean Energy Technologies has discovered a way to capture and store carbon in a chalk substance that can be used to produce cement, all in a process that can be run by renewable energy.

Cement production currently produces 8 per cent of global CO2 emissions.

The QUT process also produces hydrogen as a by-product, a clean energy fuel.

PhD researcher Olawale Oloye and Professor Anthony O’Mullane came up with the process.

O’Mullane said the solid carbonate materials produced by the process could also be used in building materials, but its primary goal was to keep carbon dioxide out of the atmosphere.

“We envision this technology would benefit emission-intensive industries such as the cement industry whose CO2 footprint is seven to 10 per cent of anthropogenic CO2 emissions due to the initial clinking (heating) steps that converts calcium carbonate into lime,” he said.

“Given that urbanisation is expected to grow over the next 50 to 100 years, the demand for cement and concrete will continue to increase and with it the need to significantly reduce the industry’s CO2 footprint.

Other products that could be produced by the process were strontium carbonate and manganese carbonate which both have industrial uses.

O’Malley said seawater could be used.